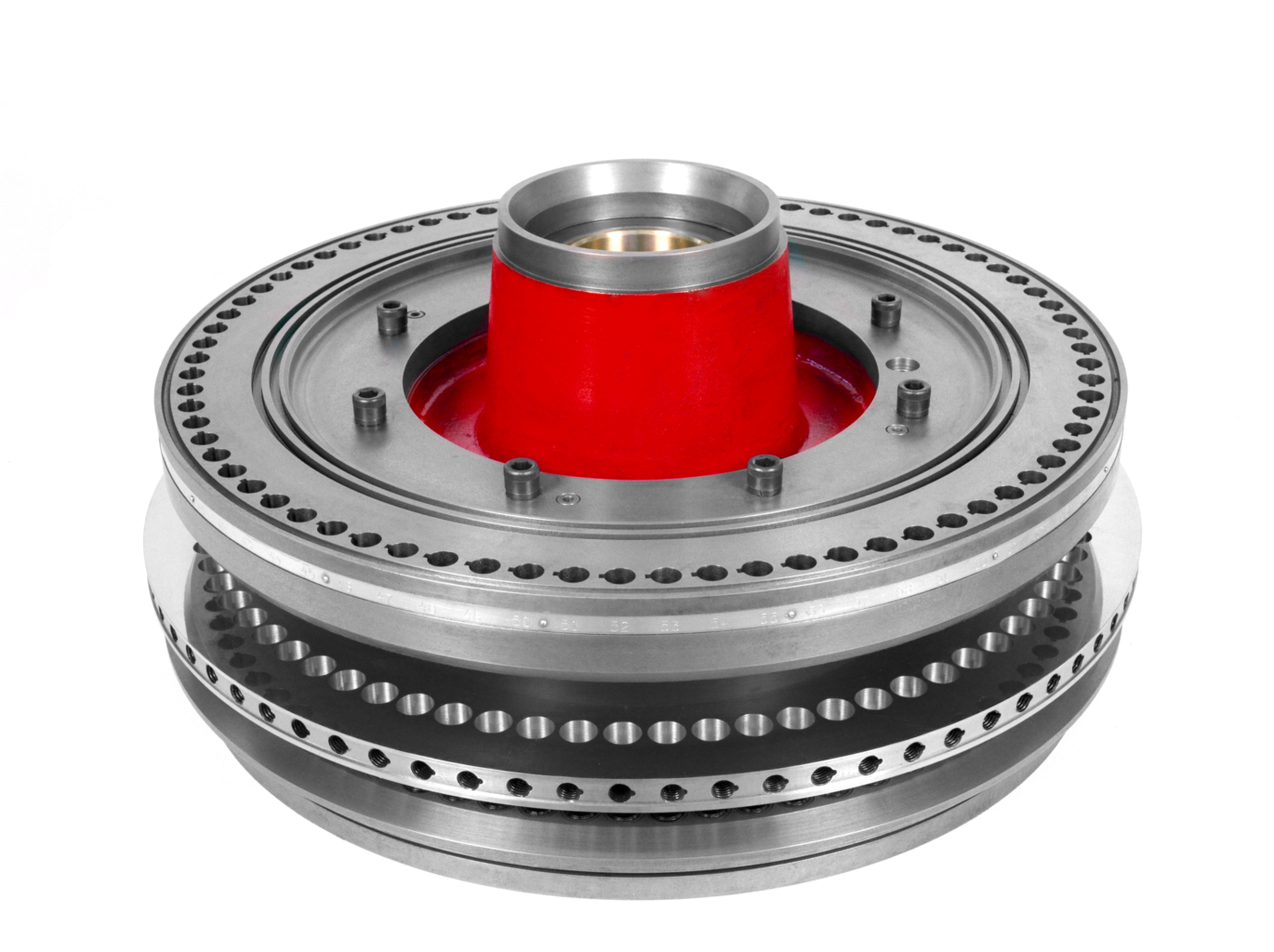

Increase Strength

Stainless Steel Die Tables provide increased strength. In the past, standard mehanite die tables have been prone to “cracking in the web” due to excessive torque applied to the die locks. Stainless Steel increases the die pocket strength. This dramatic improvement practically eliminates the potential of cracked webbing between the die pockets (particularly on fragile small die machines).

Increase Productivity

Due to the increased strength of the die table, additional stations may be added to a new B or D turret for an immediate increase in productivity.

Increased Wear Resistance

Stainless Steel provides increased hardness to 49RC as compared to the cast iron at 26RC. The increase in hardness significantly increases the die table’s resistance to wear.

Tolerances Remain Higher

A secondary benefit of increased wear resistance and strength is maintaining tight turret tolerances. Maintaining tight turret tolerances improves tablet press performance. Production yields and weight control remains higher with a turret in excellent condition.

Easier to Clean/ Simplify Changeover

Stainless Steel die tables are much easier to clean making product changeovers and validation easier. Single piece easy install punch restraints.

Tooling lasts longer and press runs faster

Because of our special cold work process, IPR’s turret punch bores are smoother and wear longer. Our customers tell us that their tooling lasts longer and they can run their presses faster.

Reduce Friction

Due to the smooth finish and hard surface area of the die table, customers have documented reduction of friction. Additionally, the ability of the scrapers to clean excess materials effectively is enhanced.