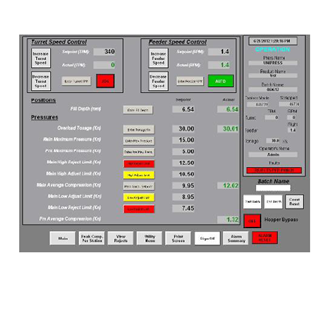

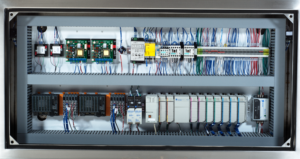

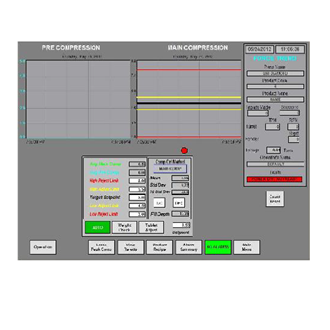

Incorporating Allen Bradley PLC and HMI technology, the configurable TPAC System ensures compliance by incorporating the following features.

Process Control

IPR’s TPAC System provide process control for any tablet press with compression force monitoring and feedback, automatic weight control, and tablet reject functionality.

Security Access

The TPAC System incorporates a security matrix with configurable and user defined groups. Window integrated security enables Active Directory or Local Windows Security Integration. RFID badge readers offer password token capability utilizing employee badges.

Audit Trail

Data logging to Sequel Server for record entry or changes provides traceability. Meaning for each record change is also recorded. Standard reports in combination with reporting tools provide audit trail visibility.

Electronic Signature

Electronic signature and approval capability enables verification and authorization on critical process control functions. E-signatures are configurable per individual user requirements.

OEE & IoT

Utilizing the TPAC System’s OPC capability, the TPAC System provides integration with OEE and IoT controllers and gateways. Dashboard reports provide an accessible snapshot of tablet machinery productivity and efficiency.

Features

- Highlights

- Robust and Proven Design

- User Friendly, Feature Rich

- Configurable Modular System

- Portable to Multiple Presses

- Security

- User Access Control

- FactoryTalk View User Security or

- Windows Security Integration

- Optional Indala or HID Card Reader

- Hardware Features

- Allen Bradley CompactLogix PLC

- PanelView Plus or Industrial PC

- High Speed Analog I/O

- Strain Gage Mechanisms

- Single or Group Tablet Reject

- Single-Piece Machined Discharge Chutes

- Software Features

- Allen Bradley FactoryTalk View

- Microsoft Sequel Server Express

- Main & Pre Compression Force Display

- Automatic Weight Control via Average Force Feedback

- Tablet Reject via Individual Punch Station Force Limits

- Automatic Setup

- Product Recipe

- Press Parameters & Calibration

- Operation Screen with Tablet Check

- Rejects Per Station Screen

- Optional Audit Trail

- Optional Batch Reporting

- Optional OEE Interface

- Optional Central Database

- Optional Tablet Tester Interface

- Optional Deduster Interface

Your Benefits

Improved Quality Assurance

- Automatic Tablet Weight Control

- Reject Out of Specification Tablets

- Compression Force Monitoring & Statistics

- Data Logging & Reporting

Improved Productivity & Efficiency

- Tablet Press Diagnostics and Troubleshooting

- Alarm Messaging

Improved Product Setup

Product Recipes and Automatic Setup Optimizes Press Setup

Improved Troubleshooting

- Modem for remote support

- Eliminate proprietary difficult to troubleshoot circuit boards